Thermosetting composite polystyrene board: What are the differences between thermosetting composite polystyrene board and local standards, EPS polystyrene board-graphite polystyrene board

Time:

08 Jul,2020

Source:

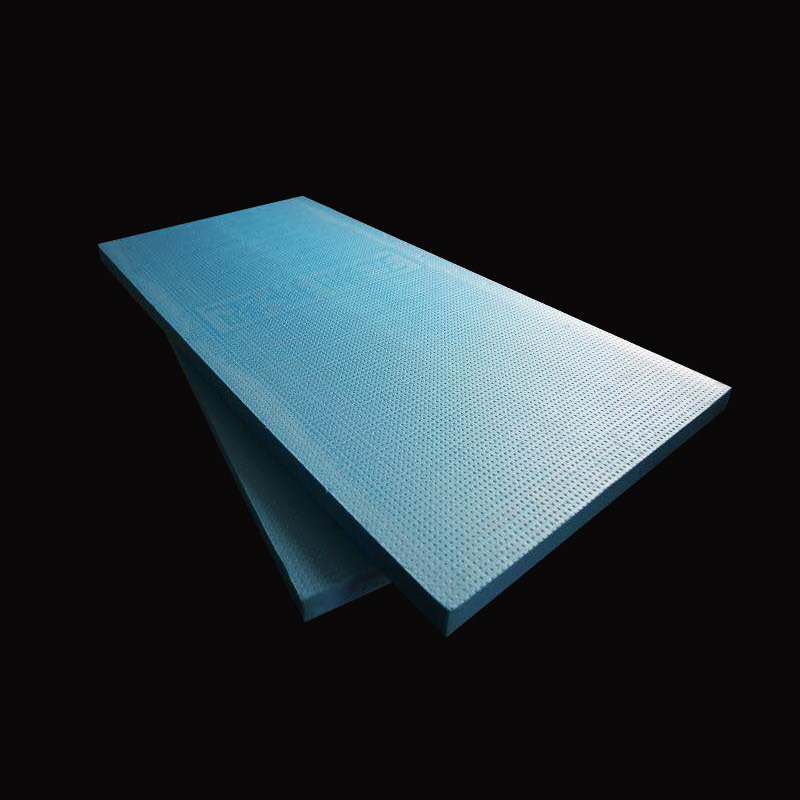

Thermosetting composite polystyrene board is a new type of insulation board with various types and can be used in many occasions. It has been applied in many occasions after the market and performed well. According to the industry standard officially implemented by the country in 2018, TEPS thermoset The composite polystyrene board has been fully implemented. Is there any difference between the TEPS thermosetting composite polystyrene board in the industry standard and the local standard?

For example, the local standard in Shandong is polymer polystyrene board, Sichuan is inorganic permeable insulation board, Hebei is siliceous polystyrene board, Inner Mongolia is AEPS polystyrene board, and Jiangsu is thermosetting composite polystyrene foam insulation board. Different, although the name is different, the product is exactly the same.

What are the differences between Wuzhou's recommended thermosetting composite polystyrene board and local standards:

1. Thermosetting composite polystyrene foam insulation board uses polystyrene foam particles or plates as the insulation matrix and uses a treatment agent to compound the plate-shaped product, referred to as "thermosetting composite polystyrene board (TEPS)", and its composite process Mainly include particle coating, mixed molding or substrate penetration, etc. It has a certain shape retention ability under fire conditions and does not produce molten drips.

2. AEPS is made of traditional EPS polystyrene board or EPS graphite polystyrene board and new inorganic materials to infiltrate, solidify, polymerize, fill uniformly and isolate the air, so that the polystyrene particles are surrounded by special inorganic material crystals with fire resistance. , Thereby completely changing the original polystyrene board's shrinkage and droplet defects when exposed to fire, and maintaining the excellent physical properties of the original polystyrene board. Its product features: unparalleled fire protection.

3. The fireproof performance of siliceous polystyrene board can reach Class A, non-combustible, and it has excellent heat preservation performance. The technology of siliceous modified polystyrene board applies cross-field and cross-disciplinary polymer technology, introduces a new concept of fire protection, and completely abandons the molecular modification of original boards and other materials, or the route of adding flame retardants.

4. The board produced by the inorganic composite polystyrene board equipment is resistant to tension, which solves the problem that inorganic materials are not thermally insulated, and the anti-folding effect is very good. The fire rating can reach A level. It is a new type of material for exterior wall insulation boards today, and inorganic composite polystyrene board The equipment can also produce color steel sandwich panels.

Color-steel composite panels that can not only be fireproof but also heat-preserving, and this equipment can solve the problem that people are also very strict about the foam board in the color steel plate in terms of safety awareness. The inorganic permeable polystyrene board uses inorganic materials to infiltrate the polystyrene board through the equipment, so that the inorganic material enters the polystyrene board, so that the polystyrene board achieves the effect of flame retardancy and fire prevention.

The above is the content collected by the editor of Hebei Wuzhou Kaiyuan Environmental Protection New Material Co., Ltd. for everyone. If necessary, please contact us.

Key words:

More News

2022-08-11

The comprehensive performance of graphite polystyrene board is very good. Its safety effectiveness has been certified by many engineering project cases. According to the specific conditions and technical standards at this stage, graphite polystyrene board is also a safe wall insulation Raw materials are now widely used in various engineering constructions.

2022-08-11

Thermosetting composite polystyrene board is a new type of insulation board with various types and can be used in many occasions. It has been applied in many occasions after the market and performed well. According to the industry standard officially implemented by the country in 2018, TEPS thermoset The composite polystyrene board has been fully implemented. Is there any difference between the TEPS thermosetting composite polystyrene board in the industry standard and the local standard?

2022-08-11

Thermosetting composite polystyrene board High polymer thermal insulation board is an integrated thermal insulation board, so it can be seen in many construction sites today. For many construction teams, this kind of thermal insulation material is convenient for engineering construction, and it can also guarantee very good consideration. For many customers, this kind of raw material construction can promote the beauty of all walls after construction.

2022-08-11

Thermosetting composite polystyrene board Polystyrene insulation board is used as the insulation layer, the full name is polyethylene insulation foam board, alias insulation foam board or EPS board. It is made of expandable polyethylene beads with volatile liquid styrofoam, which is pre-heated and formed into a milky white solid with a fine omental sac structure after being pre-heated.

Contact Wuzhou Zhengyuan