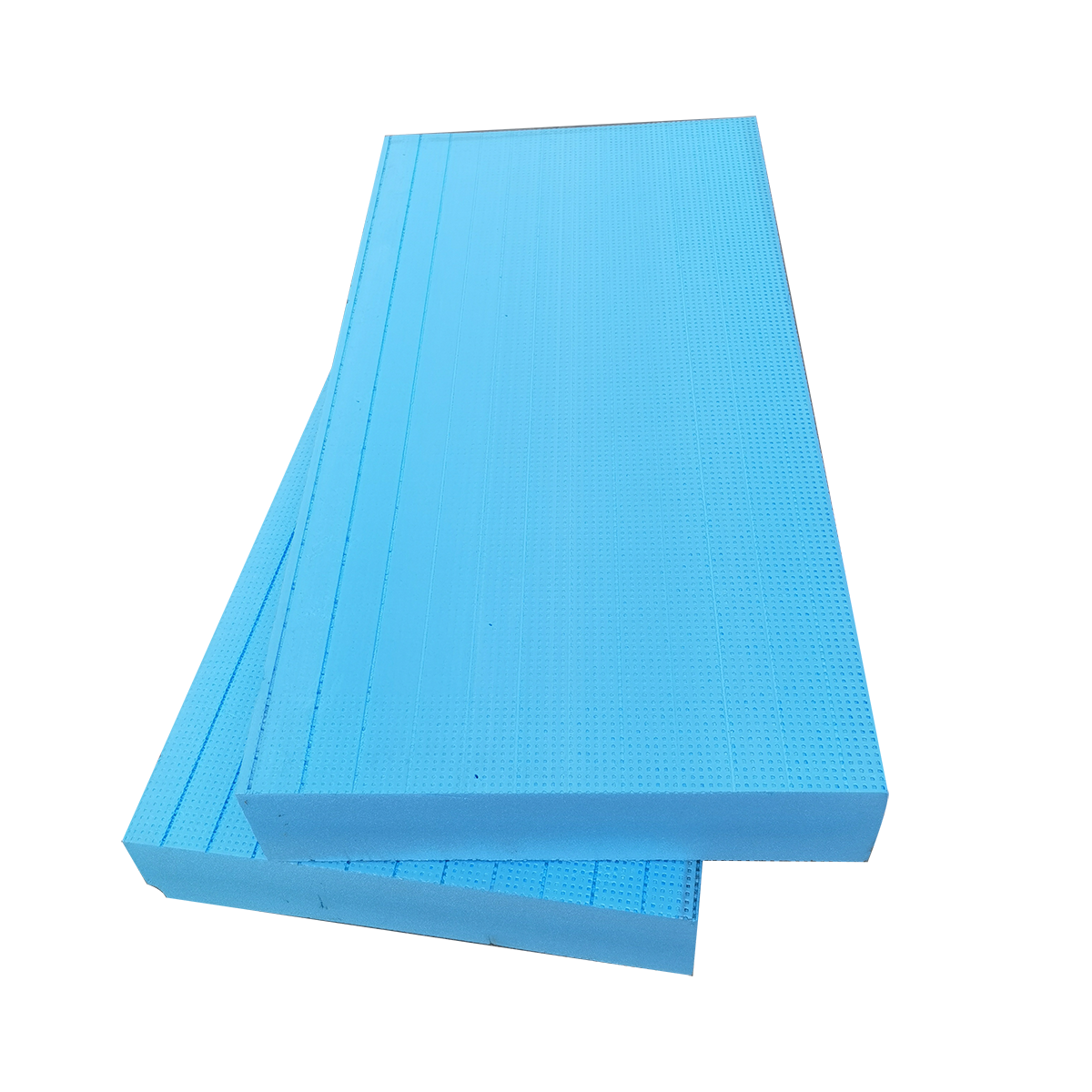

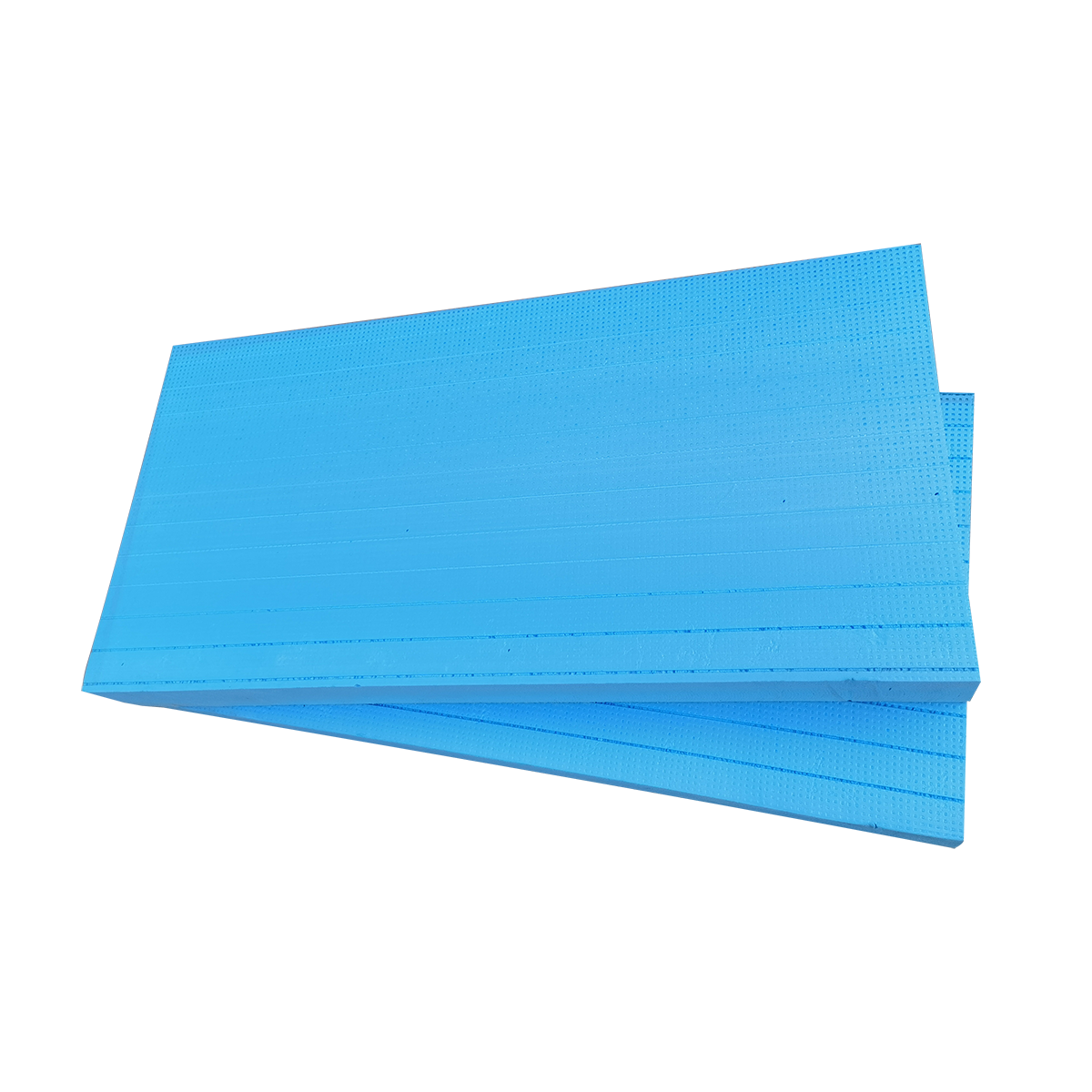

Extruded board

Keywords:

Classification:

Detail

**Extruded Board**

Extruded boards are versatile materials widely used in various industries due to their unique properties and manufacturing processes. These boards are primarily made from thermoplastics, such as polystyrene, polyethylene, and polypropylene, which are heated and forced through a die to create a continuous profile. This article delves into the manufacturing process, types, applications, advantages, and environmental considerations of extruded boards.

**Manufacturing Process**

The production of extruded boards begins with the selection of raw materials. The chosen thermoplastic resin is fed into an extruder, where it is subjected to heat and pressure. The extruder consists of a screw that rotates within a heated barrel, melting the plastic as it moves along. Once the plastic reaches a specific viscosity, it is forced through a die, which shapes it into a flat board.

After exiting the die, the extruded board is cooled, typically using a water bath or air cooling system. This cooling process solidifies the board, maintaining its shape and dimensions. Once cooled, the board can be cut to desired lengths and subjected to additional processes such as surface treatment or lamination, depending on the intended application.

**Types of Extruded Boards**

Extruded boards can be classified into several types based on the materials used and their specific properties.

1. **Polystyrene Boards**: These are lightweight and have excellent insulation properties, making them ideal for applications in construction and packaging. They are often used in insulation panels, signage, and as a protective layer for fragile items.

2. **Polyethylene Boards**: Known for their chemical resistance and durability, polyethylene boards are commonly used in industrial applications. They are often found in storage tanks, chemical containers, and various outdoor applications due to their weather resistance.

3. **Polypropylene Boards**: These boards are known for their toughness and flexibility. They are used in applications requiring high impact resistance, such as automotive components, packaging materials, and various consumer goods.

4. **PVC Boards**: Extruded PVC boards are widely used in construction and signage due to their rigidity and resistance to moisture. They are often utilized in wall panels, roofing sheets, and outdoor furniture.

**Applications of Extruded Boards**

Extruded boards find applications across a multitude of industries. In construction, they are primarily used for insulation, wall panels, and roofing materials. Their lightweight nature and excellent thermal properties make them ideal for energy-efficient buildings.

In the packaging industry, extruded boards serve as protective materials for fragile goods. Their customizable thickness and strength allow manufacturers to design packaging that meets specific requirements, ensuring that products are well-protected during transportation.

Additionally, extruded boards are used in the automotive industry for interior components, such as door panels and dashboards. Their lightweight properties contribute to fuel efficiency, making them an attractive option for vehicle manufacturers.

In the realm of consumer goods, extruded boards are used in various applications, from household items to sporting equipment. Their versatility allows manufacturers to create innovative products that cater to diverse consumer needs.

**Advantages of Extruded Boards**

The popularity of extruded boards can be attributed to several advantages.

1. **Customization**: The extrusion process allows for a high degree of customization in terms of thickness, width, and surface finish. This flexibility enables manufacturers to meet specific design requirements for various applications.

2. **Cost-Effectiveness**: Extruded boards are often more cost-effective than other materials, particularly in large-scale production. The efficiency of the extrusion process reduces labor costs and material waste, making it an economical choice for manufacturers.

3. **Lightweight**: Extruded boards are significantly lighter than many traditional materials, which can lead to reduced transportation costs and easier handling during installation.

4. **Durability**: Many extruded boards exhibit excellent resistance to moisture, chemicals, and UV radiation, enhancing their longevity and performance in demanding environments.

5. **Insulation Properties**: Certain types of extruded boards, particularly polystyrene, offer excellent thermal insulation, making them ideal for energy-efficient building applications.

**Environmental Considerations**

While extruded boards offer numerous advantages, it is essential to consider their environmental impact. The production of thermoplastics often involves the use of fossil fuels, contributing to greenhouse gas emissions. However, advancements in recycling technologies are making it possible to reuse extruded boards at the end of their life cycle.

Many manufacturers are now focusing on producing biodegradable or recyclable extruded boards to minimize environmental harm. Using recycled materials in the production process can significantly reduce the carbon footprint associated with extruded boards.

Additionally, efforts are being made to develop more sustainable manufacturing practices, such as using renewable energy sources and reducing water consumption during production. As the industry evolves, it is crucial to strike a balance between meeting market demands and ensuring environmental sustainability.

**Conclusion**

Extruded boards are a valuable material in various industries due to their versatility, cost-effectiveness, and performance characteristics. From construction to packaging and consumer goods, their applications are vast and diverse. While environmental considerations remain a challenge, ongoing innovations in materials and manufacturing processes are paving the way for a more sustainable future. As industries continue to seek efficient and eco-friendly solutions, extruded boards will undoubtedly play a significant role in shaping the landscape of modern manufacturing.

Feedback

More Prodcut