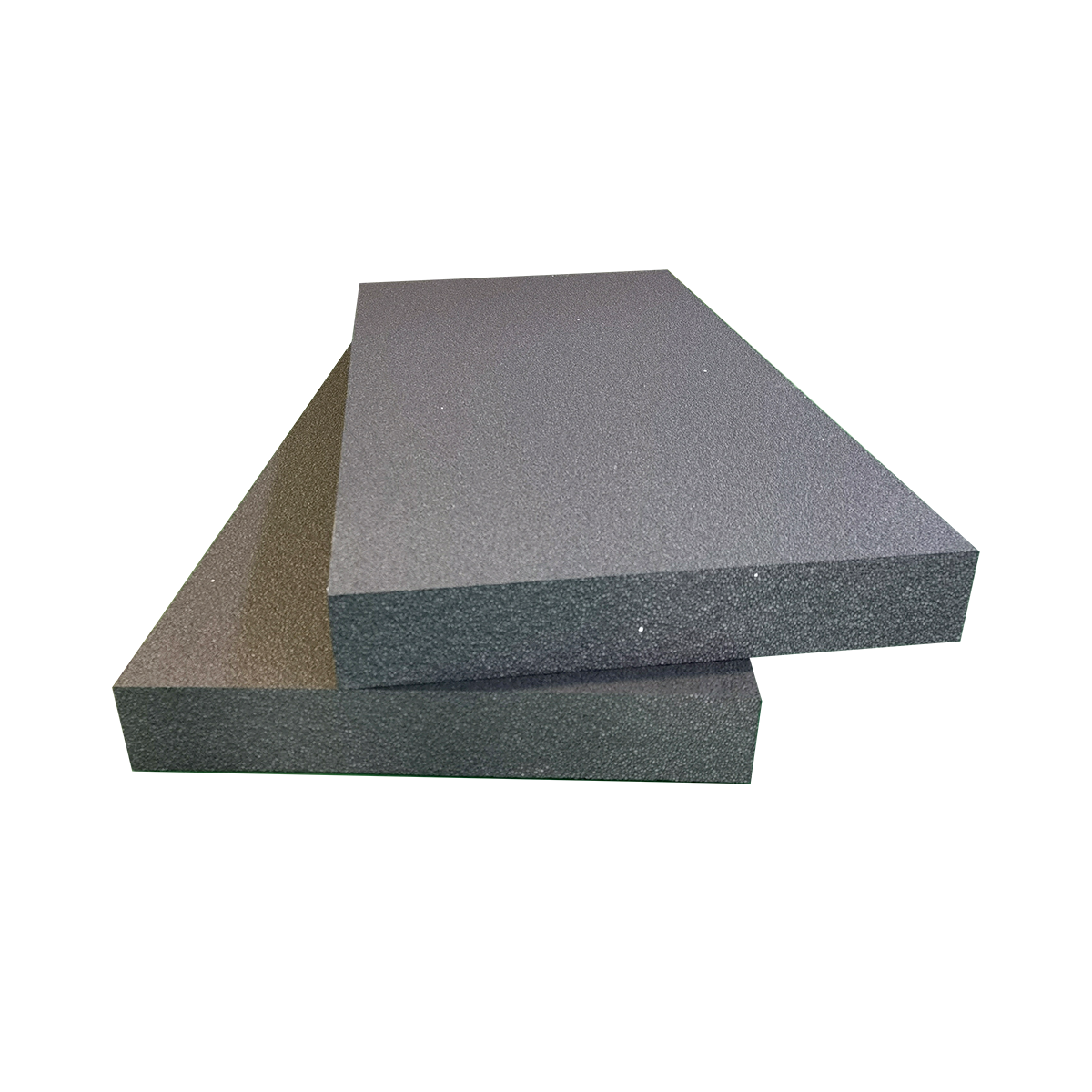

High density graphite polystyrene board

Keywords:

Classification:

Detail

High Density Graphite Polystyrene Board

Introduction

In the realm of construction and insulation materials, high density graphite polystyrene boards have emerged as a revolutionary solution. Combining the lightweight characteristics of polystyrene with the superior thermal conductivity of graphite, these boards offer an innovative approach to insulation and energy efficiency. This article will explore the composition, properties, applications, and advantages of high density graphite polystyrene boards, illustrating why they are becoming increasingly popular in various industries.

Composition and Structure

High density graphite polystyrene boards are primarily composed of expanded polystyrene (EPS) infused with graphite particles. The manufacturing process involves the expansion of polystyrene beads, which are then mixed with graphite to enhance their thermal properties. The resulting product is a board that maintains the lightweight nature of polystyrene while significantly improving its thermal conductivity.

The addition of graphite not only increases the thermal performance of the board but also improves its fire resistance. Graphite has a high ignition point, making the boards less susceptible to combustion. This unique composition makes high density graphite polystyrene boards an ideal choice for various applications where both insulation and fire safety are critical.

Thermal Properties

One of the standout features of high density graphite polystyrene boards is their exceptional thermal insulation properties. The incorporation of graphite enhances the thermal conductivity of the boards, allowing for improved heat retention and transfer. This results in energy savings, as buildings insulated with these boards require less energy for heating and cooling.

Moreover, the high density of the boards contributes to their ability to resist heat flow. This means that they can effectively minimize heat loss in winter and reduce heat gain in summer, creating a more comfortable indoor environment. As energy efficiency becomes a key concern for homeowners and builders alike, the demand for high density graphite polystyrene boards continues to grow.

Applications

High density graphite polystyrene boards are versatile and can be used in a variety of applications. They are commonly utilized in residential and commercial construction for insulation purposes. These boards are ideal for insulating walls, roofs, and floors, providing effective thermal barriers that enhance energy efficiency.

In addition to construction, high density graphite polystyrene boards are also used in refrigeration and cold storage facilities. Their ability to maintain stable temperatures makes them suitable for insulating refrigerated transport vehicles and storage units, ensuring that perishable goods are kept at optimal temperatures.

Furthermore, the boards find applications in the manufacturing of insulated panels, which are increasingly used in the construction of energy-efficient buildings. Their lightweight nature makes them easy to handle and install, reducing labor costs and construction time.

Advantages

The advantages of high density graphite polystyrene boards extend beyond their thermal properties. One of the key benefits is their lightweight nature, which simplifies transportation and installation. This characteristic allows builders to reduce overall project costs and timelines.

Another significant advantage is the boards' durability. High density graphite polystyrene boards are resistant to moisture, mold, and pests, ensuring a longer lifespan compared to traditional insulation materials. This durability contributes to lower maintenance costs over time, making them a cost-effective solution for insulation needs.

Additionally, the environmental impact of high density graphite polystyrene boards is worth noting. Many manufacturers are committed to producing eco-friendly products, and these boards can often be recycled at the end of their life cycle. This aligns with the growing trend towards sustainable building practices and materials.

Conclusion

In conclusion, high density graphite polystyrene boards represent a significant advancement in insulation technology. Their unique composition, superior thermal properties, and versatility make them an ideal choice for various applications in construction and beyond. As the demand for energy-efficient solutions continues to rise, these boards are poised to play a crucial role in the future of building materials. With their numerous advantages, including lightweight design, durability, and environmental benefits, high density graphite polystyrene boards are undoubtedly a smart investment for anyone looking to enhance energy efficiency and comfort in their spaces.

Feedback

More Prodcut