XPS sheet

Keywords:

Classification:

Detail

Extruded polystyrene foam (XPS) is the continuous extrusion and foaming of polystyrene (PS) resin, blowing agent and related additives through an extruder. Due to the closed-cell foam structure, its The comprehensive performance is very excellent, such as excellent thermal insulation performance, long-lasting, low water absorption, good dimensional stability, excellent steam permeability resistance, high compressive strength, etc., Wuzhou Kaiyuan XPS board has been widely used in many fields, mainly including: Wall Insulation, inverted roof insulation, steel roof insulation, cold storage insulation, floor heating systems, floor installation auxiliary materials, composite air ducts, color steel sandwich panels, building undersides, roadbeds, etc., among which wall insulation is the most widely used。

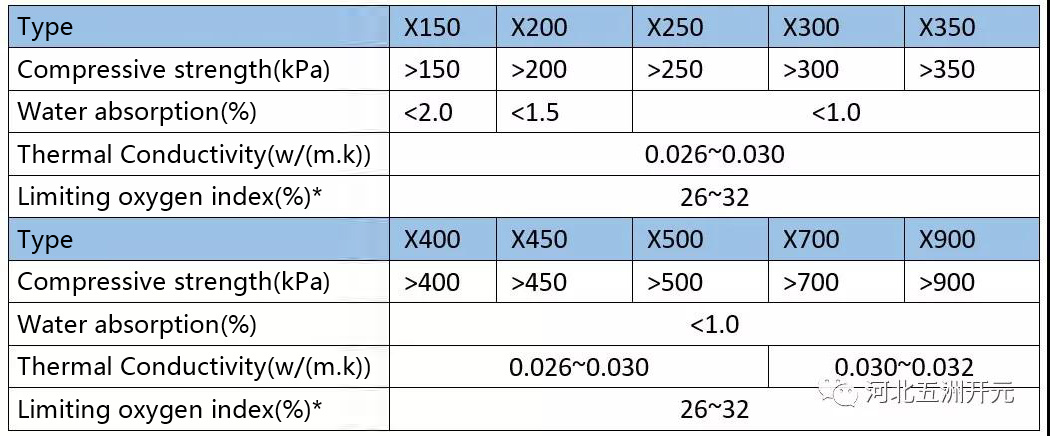

五洲开元XPS板材的性能指标

Note: *——Non-flame retardant board does not have this requirement

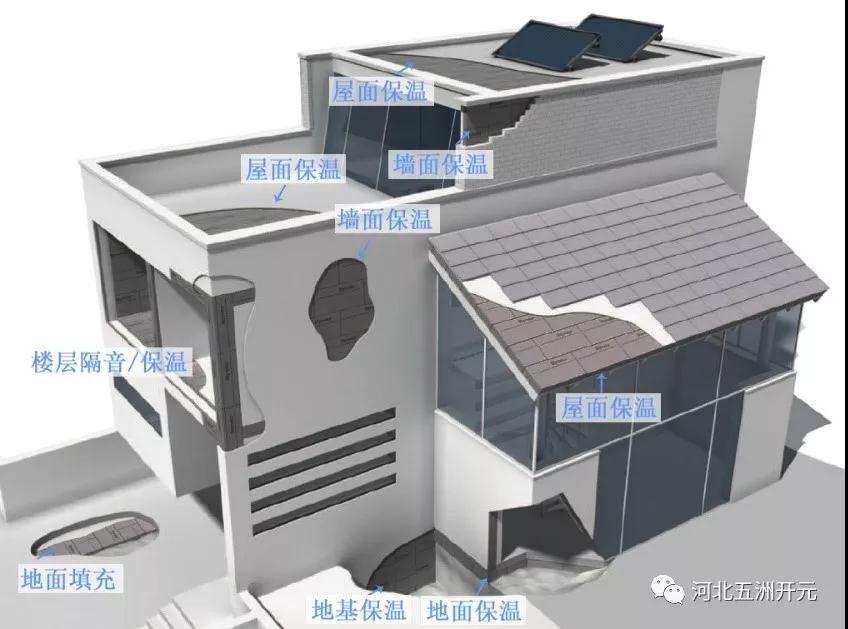

Application of Wuzhou Kaiyuan XPS Sheet

XPS board can be widely used in the construction field, including exterior wall insulation system, foundation insulation system, ground insulation system, roof insulation system, floor insulation and sound insulation, etc. High-strength products can also be used for pavement and square filling and anti-frost heave.

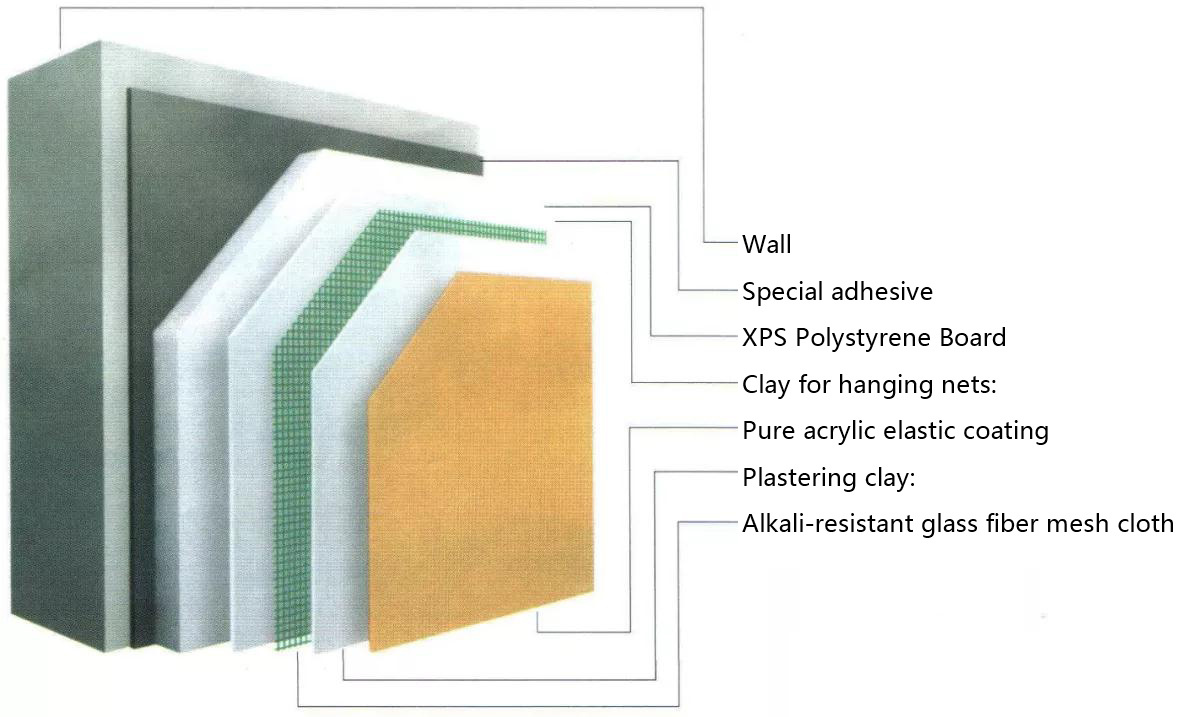

1) XPS thin plaster external wall external insulation system

XPS thin plaster exterior wall exterior insulation system uses XPS board as the core material for insulation, and uses polymer bonding mortar to paste polystyrene board on the outside of the exterior wall, and then uses polymer plastering mortar to compound alkali-resistant glass fiber cloth (or steel wire mesh) As the cover layer, it plays the role of anti-cracking and anti-seepage, forming a complete system. The main features of the plastering benzene board thermal insulation system are light weight and low thermal conductivity; obvious thermal insulation effect; it does not occupy the area of indoor use rights; completely eliminates local cold bridges and protects the wall structure; construction saves time, trouble, labor, and ease operate.

XPS thin plastering system

2) Core insulation layer of prefabricated component of prefabricated building

Traditional buildings are poured directly on the construction site, which is also called cast-in-place monolithic. As for prefabricated buildings, prefabricated components are produced in the factory and then transported to the construction site to be assembled, just like building blocks. At present, prefabricated buildings are very popular in Europe, America and Japan, and are in a stage of vigorous development in my country. According to the plan of the Ministry of Housing and Urban-Rural Development, prefabricated buildings will account for more than 50% of new buildings by 2025. Compared with cast-in-place monolithic, prefabricated buildings are faster, less restricted by climatic conditions, and produce very little construction waste.

Advantages of prefabricated buildings

1. Good quality: the components can be standardized and mass-produced, almost not affected by weather conditions, and more reliable in terms of quality;

2. Energy saving and environmental protection: reduce the waste of materials during the construction process, and greatly reduce the construction waste at the construction site;

3. Shorten the construction period: After the components are produced, the on-site assembly is pulled down, which reduces a part of the process and greatly accelerates the construction progress;

4. Save manpower: The components are produced in the factory, which reduces manpower requirements and reduces the labor intensity of construction personnel;

5. Saving templates: Since the laminated board is used as the bottom film of the floor and the external hanging board is used as the side template of the shear wall, a large amount of templates are saved.

Wuzhou Kaiyuan XPS board has high compressive strength, low water absorption, and good dimensional stability. It can be used for the core insulation layer of prefabricated building components.

Wuzhou Kaiyuan XPS board can be used for the core insulation layer of prefabricated building components

3) Thermal insulation and decoration integrated board

Integrated thermal insulation and decorative panels are also called energy-saving thermal insulation and decorative integrated panels, which are composed of adhesive layers, thermal insulation decorative finished panels, anchors, and sealing materials. There are many construction schemes, which are not only suitable for external wall insulation and decoration of new buildings, but also suitable for energy saving and decoration transformation of old buildings; it is suitable for all kinds of public buildings and the external wall insulation of residential buildings; it is suitable for the north Buildings in cold regions are also suitable for buildings in hot southern regions. The thermal insulation and decoration integrated board has a flat surface, which is simpler than the traditional thermal insulation method, and has a better thermal insulation effect, which is far better than ordinary and traditional thermal insulation methods. Due to the high strength of the board surface of the integrated insulation and decoration board, the overall structure compatibility is relatively good, and there will be no deformation due to temperature changes, sunshine, rain and other factors in the application process. Therefore, the integration of insulation and decoration The flatness of the board surface is better.

Wuzhou Kaiyuan XPS board can be used as an insulation layer for all kinds of insulation and decoration integrated boards.

Wuzhou Kaiyuan XPS board can be used for the thermal insulation layer of the thermal insulation and decoration integrated board

4) Civil engineering

XPS is a good anti-frost heave insulation material, and can change the temperature under the concrete panel. The friction coefficient of the extruded polystyrene insulation board after sandblasting or slotting on the surface of the extruded polystyrene insulation board is significantly increased, and it will not be deformed or detached under long-term use. The extruded polystyrene insulation board has extremely high compressive strength and strong impact resistance. According to different models and thicknesses, its compressive strength can reach 150~500Kpa or more, and it can withstand the ground load of various systems. The extruded polystyrene insulation board can effectively waterproof and penetrate, can effectively reduce the occurrence of soil freezing and other situations, control the ground heaving and freezing, and effectively block the ground gas from moisture damage. Extruded polystyrene insulation board has good stability and corrosion resistance. It will not age, decompose, or produce harmful substances during long-term use. Its chemical properties are extremely stable and will not be degraded due to water absorption and corrosion. Its performance declines, and its superior performance can still be maintained in a high temperature environment.

XPS insulation board is used in the insulation layer of channel engineering

Feedback

More Prodcut