Molded EPS foam parts

Keywords:

Classification:

Detail

Expandable polystyrene (expandable polystyrene) is a kind of polystyrene products added with a blowing agent. The appearance is colorless transparent bead-like particles. EPS is non-toxic, odorless, non-corrosive, has good flame retardant properties, high temperature resistance, heat insulation, sound insulation, wear resistance, and is not easy to wear. And because it belongs to a closed cell structure, it is moisture-proof, non-absorbent, and has good water resistance. It is also resistant to chemical corrosion such as acids and alkalis. And the product is easy to shape and process.

The product is not only used for beautiful appearance, but also has good processability. Therefore, it has been widely used in daily life, agriculture, transportation, military industry, aerospace industry, etc., especially in construction, packaging, electronics The fields of electrical products, ships, vehicles and aircraft manufacturing are even more popular. Such as televisions, refrigerators, washing machines, air conditioners, refrigeration systems and other household appliances, electronic meters, precision instruments, glassware, ceramics, arts and crafts and other civilian light industrial products, fish steaks for marine aquaculture, seafood freezing, vegetable preservation , Incubators, cold storage, refrigerated trucks, railways, municipal construction, etc., are all inseparable from EPS panels and packaging products.

EPS foam packaging has the following advantages:

1. Protection function: During the process of storage and transportation, commodities have to go through loading and unloading, transportation, inventory, display, sales and other links. During this period, many external factors such as impact, humidity, light, gas, bacteria, etc. will threaten the safety of commodities. The structure and materials of the packaging are very important to ensure the safety of commodities in the circulation process. Good EPS foam packaging has better protection functions and can fully guarantee the safety of the products in circulation.

2. Thermal insulation function: EPS beads have low density, fine cells and low thermal conductivity, which can effectively prevent heat transfer and play a role in thermal insulation, so it is widely used in cold chain transportation and floor heating modules.

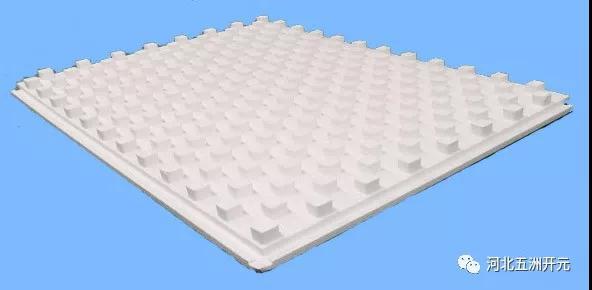

(1) Floor heating module

Floor heating module, one of the main optional components at the end of the geothermal heating system. Used to replace auxiliary materials such as insulation boards, reflective films, and staples in traditional floor heating systems. The emergence and application of floor heating modules greatly simplify the installation procedures of floor heating. The floor heating module originated in Europe. EPS is easy to shape and can be directly integrated into a mushroom head through a mold; EPS manufacturing raw materials are more controllable (the manufacturing process does not add any other chemical products), and the product quality and environmental protection are more stable. The EPS floor heating module is made of brand new materials. First, it is pre-foamed and matured by steam, and then extruded by a mold under steam catalysis by a molding machine. The EPS module is environmentally friendly and hygienic, simple in construction, and is deeply loved by the majority of owners.

(2) Packaging products

EPS is an ideal packaging material. Through the molding process, it can be processed into packaging products of various shapes and different thicknesses as required. In the case of high load, the material achieves buffering and shock absorption through deformation, energy absorption, energy decomposition, etc., and at the same time has the functions of heat preservation and heat insulation.

The advantages of EPS packaging include:

1) Lightweight. Part of the space of EPS packaging products is replaced by gas, and each cubic decimeter contains 3-6 million independent air-tight bubbles. Therefore, it is several to several tens of times larger than plastic;

2) It has the ability to absorb impact loads. When EPS packaging products are subjected to an impact load, the gas in the foam will consume and dissipate the external energy through stagnation and compression. The foam body will gradually terminate the impact load with a small negative acceleration, so it has a better shockproof effect;

3) Good heat insulation performance. The thermal conductivity of EPS material is only 0.038 W/(m·K), and the heat preservation effect is excellent; 4) Anti-aging and corrosion resistance. Except for prolonged exposure to high-energy radiation, the product has no obvious signs of aging. It can withstand many chemical substances, such as dilute acid, dilute alkali, methanol, lime, asphalt, etc.

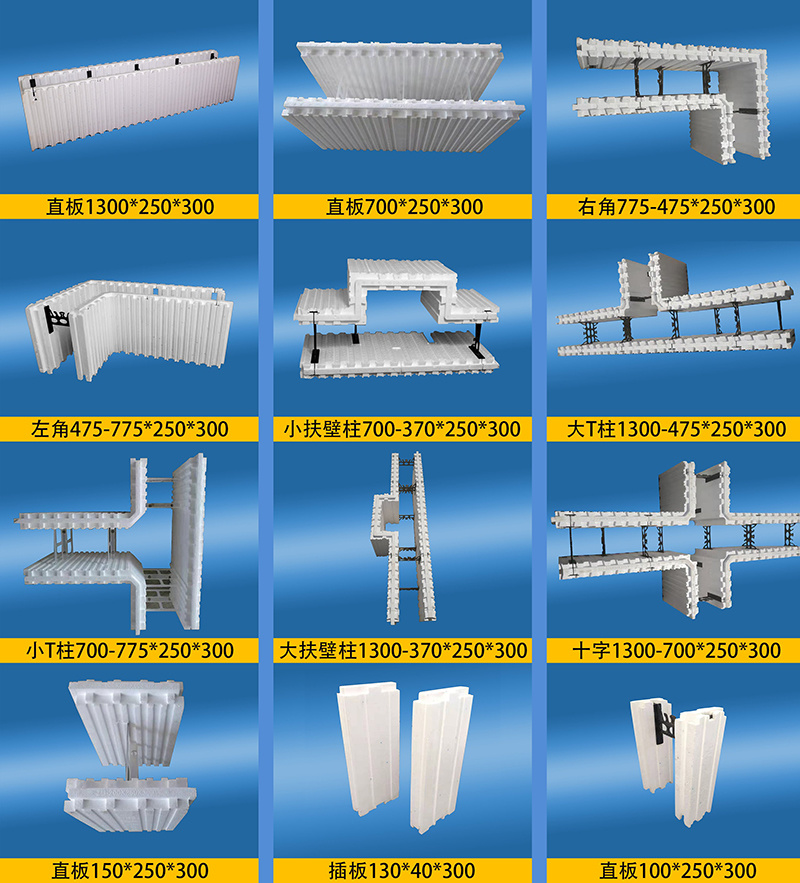

(3) Building module

EPS foam board (commonly known as polystyrene board) has been used for external wall insulation for more than 20 years. Especially in the past 10 years, more than 80% of buildings in cold and cold areas have used EPS foam boards for external wall insulation. With the gradual improvement of building energy efficiency standards, the thickness of EPS foam boards is getting thicker and thicker. EPS foam board as an external wall thermal insulation system includes EPS module thin (thick) plastering external wall thermal insulation system (referred to as paste system) and EPS cast-in-place concrete external wall thermal insulation system (referred to as cast-in-place system or ICF external wall external thermal insulation system) ). These two construction processes are complex and require multiple processes for processing, and require a very professional construction team. The EPS building module is made of expandable polystyrene beads after being heated and foamed, and then heated and formed by special equipment and molds. And made of polystyrene foam plastic profile with closed-cell structure. It already contains internal insulation layer and external insulation layer. After tying the steel bars in the middle, the module can be inserted to pour concrete. The construction is simple and quick, and the insulation effect is good. It is well received by users of self-built houses!

Feedback

More Prodcut