EPS for civil engineering

Keywords:

Classification:

Detail

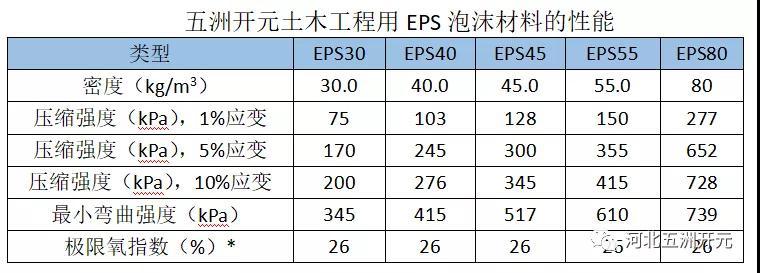

EPS foam material for civil engineering

EPS civil engineering foam has multiple functions, so it can be effectively used in various occasions, especially in soft soil foundations, slope stability and retaining walls. EPS civil engineering foam has been widely used in highways, airport runways, railway track systems, cold storage floors, sports fields, storage tanks, anti-freezing ground and building basements. EPS civil engineering foam enables engineers, architects and builders to achieve project goals by combining the functionality of synthetic materials and different types of products. Because EPS civil engineering materials have excellent strength and elasticity, many problems can be solved in engineering, and they can effectively protect against damage caused by earthquakes and vibrations, reduce noise and reduce vibration. The use of EPS as a civil engineering material is conducive to shortening the construction period and reducing the overall construction cost. As a civil engineering material, EPS is easy to construct, generally does not require special equipment, and is not affected by weather conditions. EPS can be cut into various shapes on the project site, and there are many models for designers to choose from. Its service life is the same as other materials, and it can maintain good physical properties under the conditions of use.

01. Soft soil roadbed road construction

For road sections built on soft soil roadbeds or areas with restrictions on existing tools or wetland areas, EPS civil engineering materials can be used to replace compressible soil or replace heavy fillers to solve soft soil roadbeds or The load-bearing problem of the connecting part. The high compressive strength of EPS civil engineering materials makes it enough to meet the traffic load of expressways. EPS civil engineering materials are easy to construct manually during the construction process, and these advantages can greatly shorten the construction period.

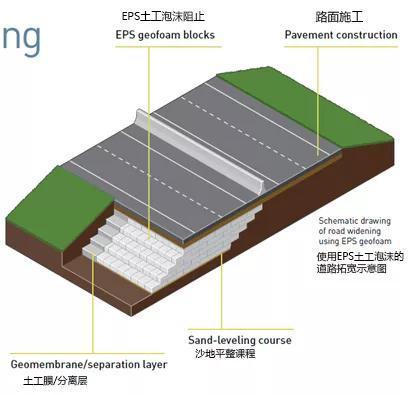

02, road widening

Smooth roads need to be widened to reduce traffic jams, so fillers are often needed to expand the pavement. If the soil in the adjacent area does not have enough bearing capacity, the widened pavement will affect the existing pavement, which will be time-consuming and laborious. project. The traditional method requires the construction of the subgrade layer by layer, and each layer needs to be compacted before the next layer is constructed. The use of EPS civil engineering foam can meet the compaction and filling requirements, reduce the construction time, and reduce the impact on the original road surface. The impact of the construction structure is small. The high compressive resistance of EPS civil engineering foam can withstand road pressure without causing unbearable loads on the underlying soil and connecting areas. In addition, the use of EPS civil engineering foam can build steeper roadside slopes than sand and gravel roadbeds, thereby reducing the cost of road construction.

03. Bridge head construction

Because EPS civil engineering foam has excellent compressive strength, it can meet the requirements of road load without exerting great pressure on the underlying soil. Compared with traditional embankment infills, EPS civil engineering foam can significantly reduce the lateral force (lateral force is proportional to the amount of backfill) on the bridgehead retaining wall, foundation and other fixed structures. This makes it possible to design other walls of the bridgehead river. A lower level of static and dynamic forces can be considered, which can save costs.

04. Filling under the bridge

With a reasonable design, EPS civil engineering foam can be used for the underfill of the bridge. The weight of EPS civil engineering foam is very light, and the pressure on the foundation soil is very small. Especially when the existing bridge's load-bearing capacity is insufficient, EPS civil engineering foam filling can be used to enhance the load-bearing capacity of the bridge, especially when the soil under the bridge is relatively loose.

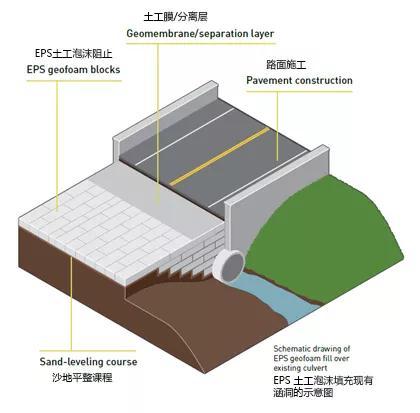

05. Culverts, pipelines and embedded systems

In engineering, there are often constructions on existing underground structural components, but the original design did not take into account the increased bearing capacity. Compared to removing or enhancing existing underground structures, using EPS civil engineering foam instead of traditional sand and gravel filling is a more economical choice.

06, foundation repair

EPS civil engineering foam can be used for foundation repair. Its weight is very light, which can reduce the bearing capacity of the underlying soft soil, reduce settlement, and solve the problem of the bearing capacity of the road surface.

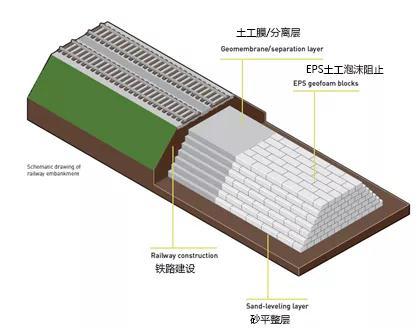

07. Railway roadbed

EPS civil engineering foam has excellent compressive strength and can be used to construct railway subgrades. Its strength meets the requirements, and it can be used to construct railway embankments on existing soil roads. When the railway passes through soft soil roads such as river canals or lake embankments, the use of EPS civil engineering foam can avoid the settlement of the connecting part of the bridge body and the settlement of the soft soil part.

08. Artificial landscape

EPS civil engineering materials can create man-made landscapes without adding existing ground and underground facilities. Examples include building roof gardens on the roofs of urban buildings.

Feedback

More Prodcut